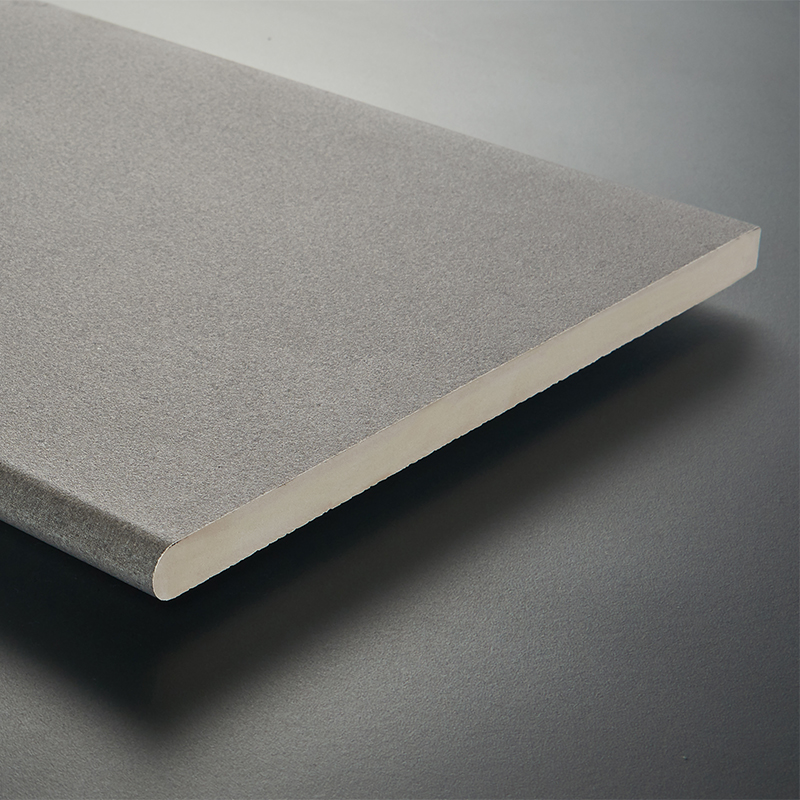

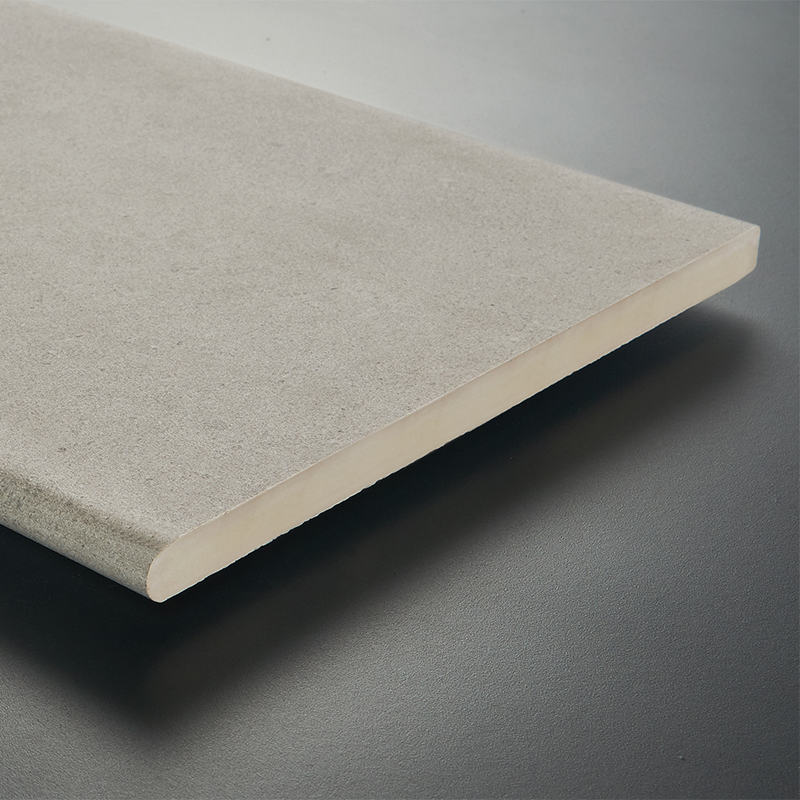

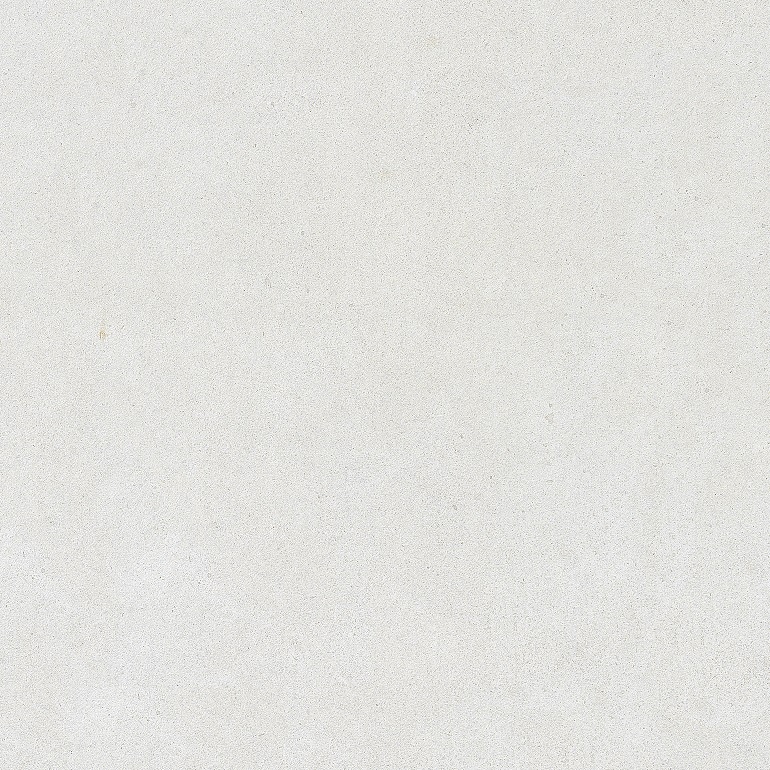

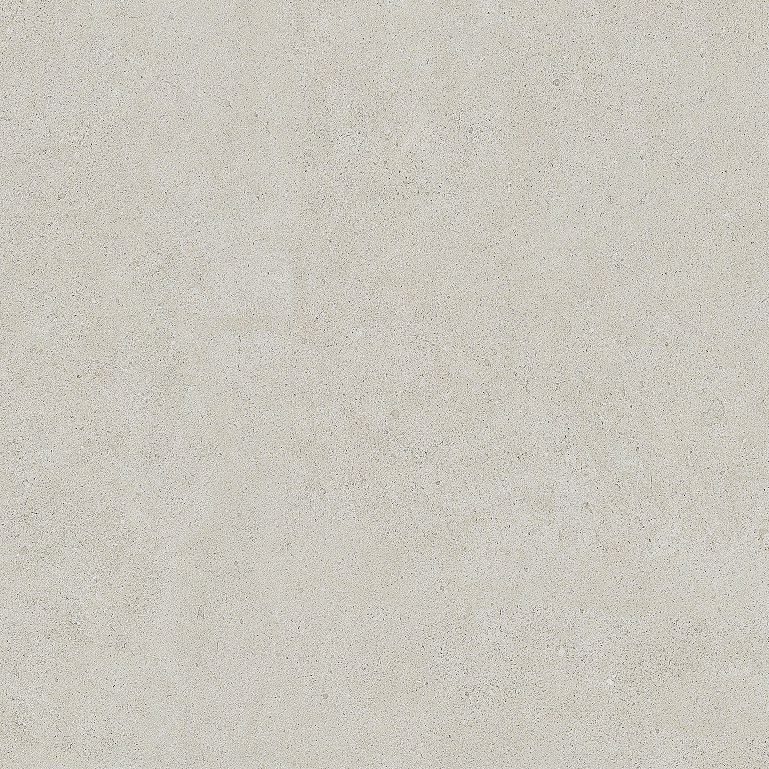

Semen Paradigma Genteng Porselen Full-Body Ing 600x600mm&450x450mm Ujung Unrectified&2cm Paver Bullnose Genteng

PUTIH

TORTORA

KELABU LUR

KELABU

GRAFIT

| KARAKTERISTIK TEKNIS | METODE UJI | STANDAR | NEX-GEN | ||

| DIREKTIFIKASI | UNRECTIFIED | DIREKTIFIKASI | UNRECTIFIED | ||

| PENGUKURAN & RUMUSAN LUWIH | |||||

| LENGTH LAN WIDTH | EN ISO 10545-2 | ± 0,6% | ± 0,6% | +0,02% ~+0,03% | -0,13% ~+0,05% |

| ± 2 mm | ± 2 mm | +0,2 mm | -0.6mm ~+0.2mm | ||

| KETEBAL | EN ISO 10545-2 | ± 5% | ± 5% | -2,7% ~+0,2% | -0,9% ~+0,4% |

| ± 0,5 mm | ± 0,5 mm | -0,3 mm | -0,1 mm ~ 0 | ||

| STRAIGHTNESS saka sisih | EN ISO 10545-2 | ± 0,5% | ± 0,5% | -0,05% ~+0,02% | -0,05% ~+0,04% |

| ± 1,5 mm | ± 1,5 mm | -0.28mm ~+0.13mm | -0,2 mm ~ + 0,2 mm | ||

| SIFAT FISIK | |||||

| BANYUPENYERAPAN | EN ISO 10545-3 | ≤0,5% | 3% | ≤0,1% | 3% |

| BREAKING STRENGTH | EN ISO 10545-4 | ≥1300N | ≥1000N | 2470 | ≥1200N |

| MODULUS RUPTURE | EN ISO 10545-4 | ≥35N/mm² | ≥22N/mm² | 51 | ≥30N/mm² |

| RESISTANCE TO ABRASION | EN lSO 10545-7 | LAPORAN menyang KELAS ABRASION | Kelas 4 | KELAS 3 | |

| LAPORAN SIKLUS LULUS | 2.100r | 1.500r | |||

| THERMAL SHOCK RESISTANCE | EN ISO 10545-9 | Ora ana cacad kudu katon | LULUS | LULUS | |

| RESISTANCE FROST | EN ISO 10545-12 | Ora ana cacat lumahing UTAWA Retak kudu katon | LULUS | LULUS | |

| SLIDER 96 SLIP RESISTANCE,UJI PENDULUM BASAH | MINAT AS 4586:2013 | - | - | ||

| MATT | P3 | P2 | |||

| LUKAS | P4 | P4 | |||

| SIFAT KIMIA | |||||

| RESISTANCE KIMIA TO BAHAN KIMIA RUMAH TANGGA & KOLAM RENANG URAH | EN ISO 10545-13 | MINIMUM GB | MINIMUM GB | A | A |

| RESISTANCE TO STAINING | EN ISO 10545-14 | KELAS MINIMUM 3 | KELAS MINIMUM 3 | KELAS 4 | KELAS 5 |

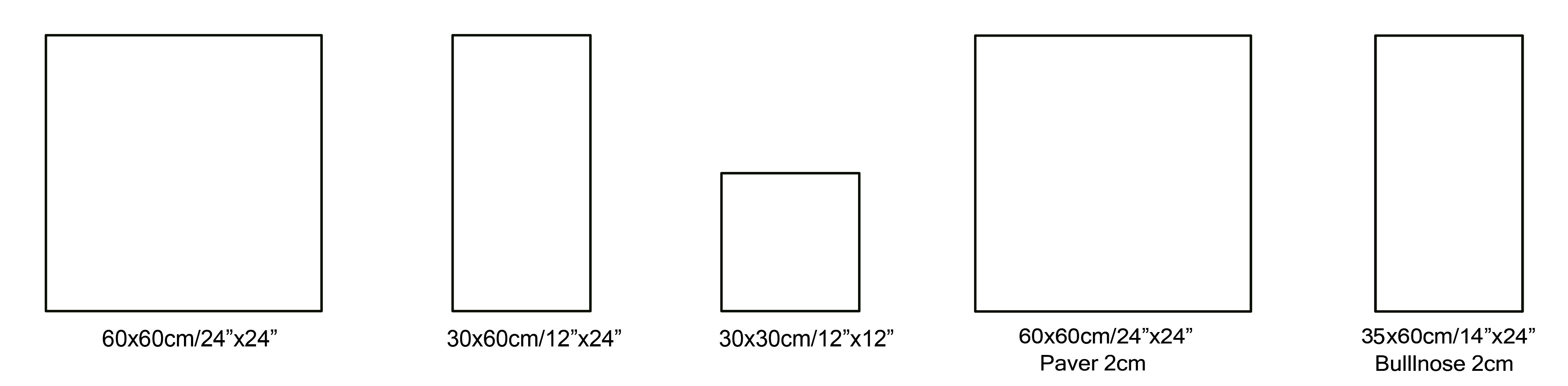

| SERI | UKURAN | PCS/CTN | M²/CTN | M²/ PLT | CTN/PLT | KG/PLT |

| PARADIGMA DIBUAT | 600x600mm/24"x24" | 4 | 1.44 | 57.6 | 40 | 1.260 |

| 300x600mm/12"x24" | 8 | 1.44 | 57.6 | 40 | 1.260 | |

| 300x300mm/12"x12" | 11 | 1 | 54 | 54 | 1078 | |

| Paver 600x600x20mm | 2 | 0.72 | 28.8 | 40 | 1.320 | |

| 350x600x20mm Bullnose | 2 | 0.42 | 26.88 | 64 | 1280 | |

| PARADIGMA UNRECTIFIED | 450x450mm/18"x18" | 5 | 1.0125 | 72.9 | 72 | 1.310 |

| 300x300mm/12"x12" | 12 | 1.08 | 84.24 | 78 | 1420 |

* Kothak bisa beda-beda ing ukuran, bobot, werna, pola, veining, tekstur, daya tahan, kapadhetan, permukaan lan finish saka batch menyang batch.Rating slip minangka indikasi lan bisa beda-beda kanggo saben klompok kothak.Disaranake supaya tes anyar ditindakake kanggo saben batch kothak yen sertifikat peringkat slip dibutuhake.Gambar produk sing ditampilake mung kanggo tujuan ilustrasi lan dudu perwakilan sing tepat saka produk kasebut.

Tulis pesen sampeyan ing kene lan kirimake menyang kita