Equipment and Production Process of Sintered Stone

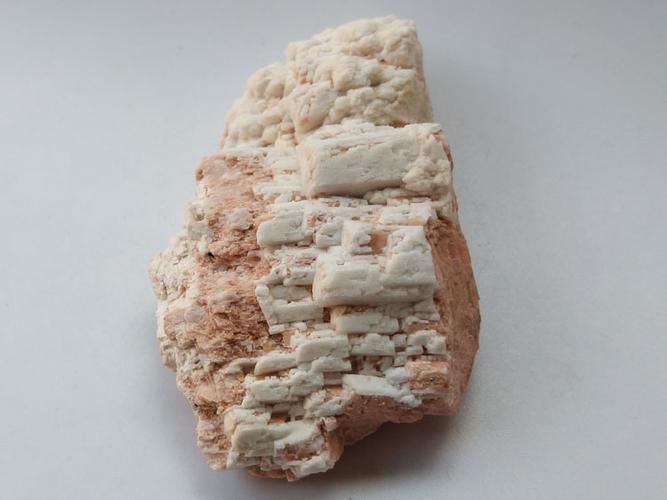

1. Main Raw Materials

Sintered stone is mainly made of mineral rock, potassium sodium feldspar, kaolin, talc and other raw materials, pressed by a press of more than 15,000 tons, combined with advanced production technology and fired at a high temperature above 1200℃.

The core equipment mainly includes: ball mill, spray tower, full body loading machine, forming press, digital ink-jet printer, digital dry grip, kiln, polishing equipment, automatic testing equipment, etc.Among them, the presses that can press rock slabs mainly include the following types: Sacmi continua+, System LAMGEA, SITI B&T and China Press Machine giants KEDA and HLT.3. types of Production Technical Solutions:

02. Roll forming

The core of the SACMI CONTINUA+ continuous molding production line is the PCR pressing equipment, which can obtain greater pressing force and higher density than traditional presses to form sintered stone. The pressing process is realized by two very hard motorized belts. The powder is stored on the lower steel belt and runs inside the machine. The two steel belts and the two pressing rollers work together to realize the pressing and forming. The powder is gradually "continuously" pressed under pressure. The width and final length of the finished product can be flexibly selected and fixed according to the needs, just change the cutting position of the pressed material, typical sizes: 1200, 2400, 3000 and 3200mm.

CONTINUA+ can cut the raw slab into smaller sizes, such as: 600x1200, 600x600, 800x800, 800x2400, 1500x1500, 750x1500, 900x900mm, etc. The maximum size is 1800X3600, the thickness can be from 3-30mm.

03. Dry pressing traditional molding

KEDA KD16008 press and HLT YP16800 press adopt dry pressing traditional forming method. In 2017, HLT YP16800 press was officially put into production in Monalisa Group and successfully produced 1220X2440mm sintered stone. In the same year, Kodak KD16008 super-tonnage press was exported to India.

Post time: Feb-05-2023