he soaring price of natura gas and the mba ance of gas cost wi make Guangdong ceramic enterprises ose their production advantages?

The soaring price of natural gas and the imbalance of gas cost will make Guangdong ceramic enterprises lose their production advantages?

Last week, the building ceramics industry was still "rising".

The first one is the price of natural gas. Relevant monitoring data show that on February 23, the average price of domestic LNG(Liquified Natural Gas) was 8090 yuan / ton, an increase of 4223 yuan / ton compared with 3866.67 yuan / ton at the beginning of the month, an increase of 109.22% within the month; Compared with the same period last year, it rose 173.31%, and some regions have exceeded 9000 yuan/ton.

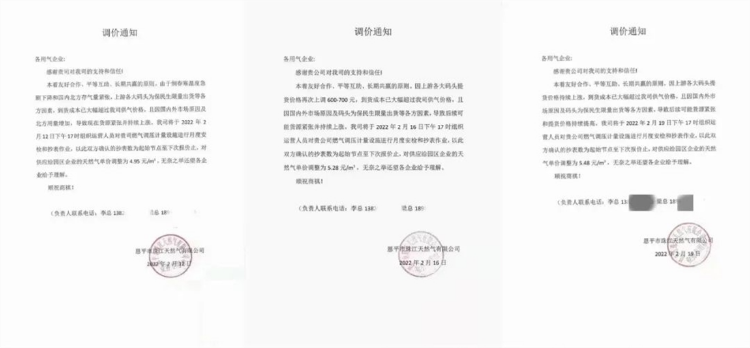

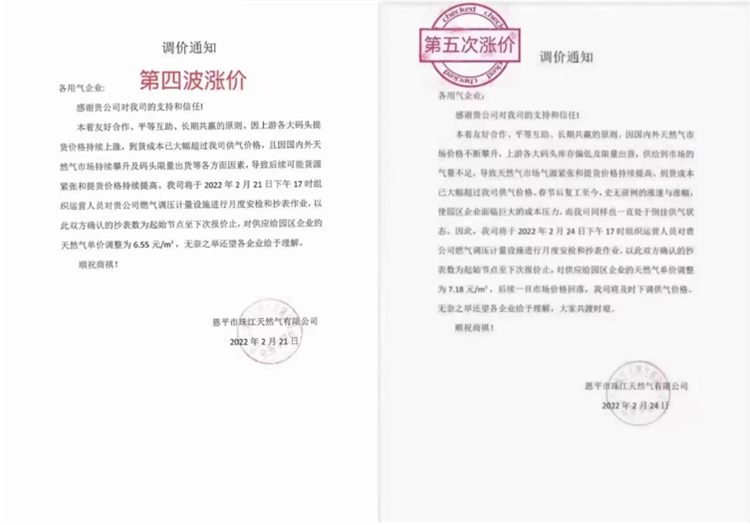

Specifically,the price of natural gas in Enping production area of Guangdong has five consecutive rises within 12 days:

On 12th February , the gas price increased from 3.75 yuan / m ³ Up to 4.95 yuan / M ³;

On 16th February, the gas price was raised again to 5.28 yuan / m ³;

On 19th February, the gas price was raised to 5.48 yuan / m³ for the third time ;

On 21st February, the gas price was raised to 6.55 yuan / m³ for the fourth time ;

On 24th February, the gas price was raised to 7.18 yuan / m³ for the fifth time。

At present, the latest current price of natural gas in the production area is 7.18 yuan / m ³, Compared with before the price increase, the price increase has exceeded 92%. It is also reported that last week, the price of Qingyuan LNG (liquefied natural gas) has exceeded 10000 yuan / ton, which is roughly converted to 7.14 yuan / m ³。 Jiajiang natural gas company issued the notice on the price adjustment of the advance floating gas payment, saying that due to the continuous rise of the landed price of imported LNG natural gas, the extra gas price in February was 7.28 yuan / m³, and the advance gas price of ceramic enterprise was temporarily 1.1 yuan per cubic meter to collect the advance floating gas payment in February. According to the relevant person in charge of a ceramic enterprise in Gao'an, the LNG canned gas in Gao'an reached 7 yuan / m³ on 26th February ……

At the same time, the price of raw materials is also rising gradually. Since the beginning of the year, ceramic body raw materials and chemical raw materials such as aluminum ore, zirconium silicate, ink and color glaze have increased significantly. Among them, the price of zirconium silicate has exceeded 21000 yuan / ton, an increase of about 30% over the beginning of the year. The latest news shows that a number of titanium dioxide enterprises will also adjust their prices in the near future, with an increase of $150-400 / ton.

With the rising prices of energy and raw materials, the ceramic tile production cost of ceramic enterprises is also rising. After March, there will be a peak sales season in the home decoration market after March. Some analysts believe that the ex factory price of ceramic tiles will not be reduced in the first half of the year. If the prices of raw materials, chemical raw materials and energy continue to rise, the possibility of rising the price of ceramic tiles will not be ruled out.

In fact, with the rise of natural gas prices, ceramic enterprises in Guangdong, Jiangxi, Sichuan and other production areas have announced to increase the ex factory price of ceramic tiles under cost pressure, and even enterprises that have ignited and resumed production are ready to stop kilns.

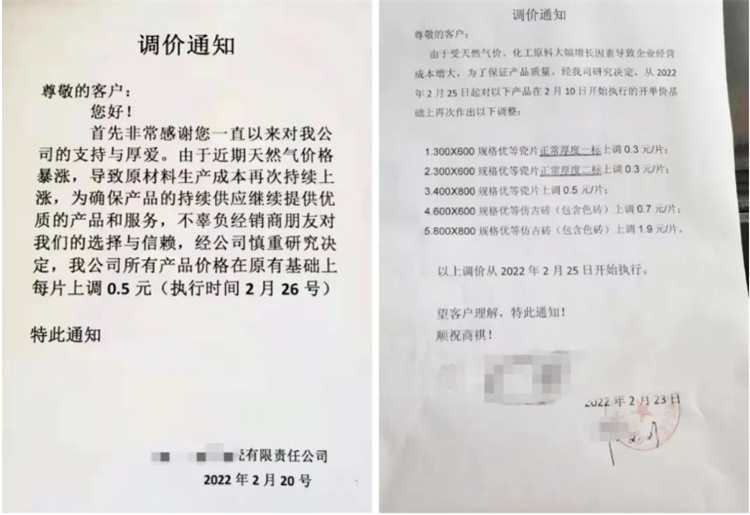

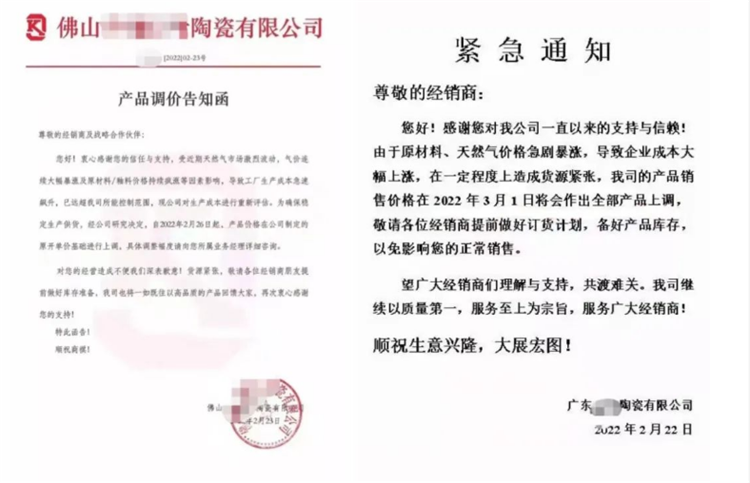

A number of ceramic enterprises have raised prices one after another

There is no large-scale price rise tide as a whole

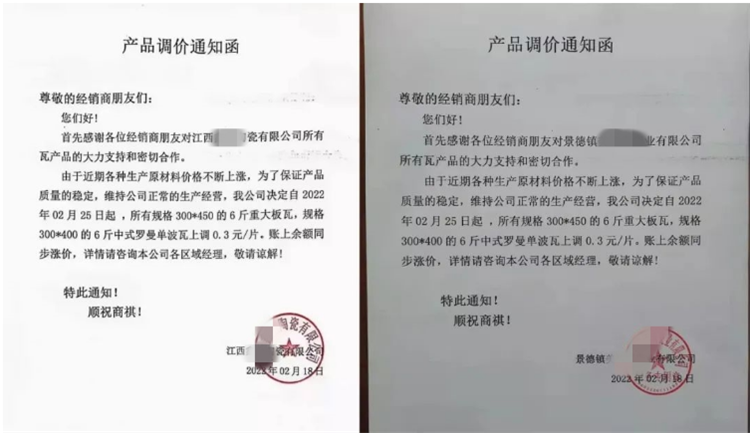

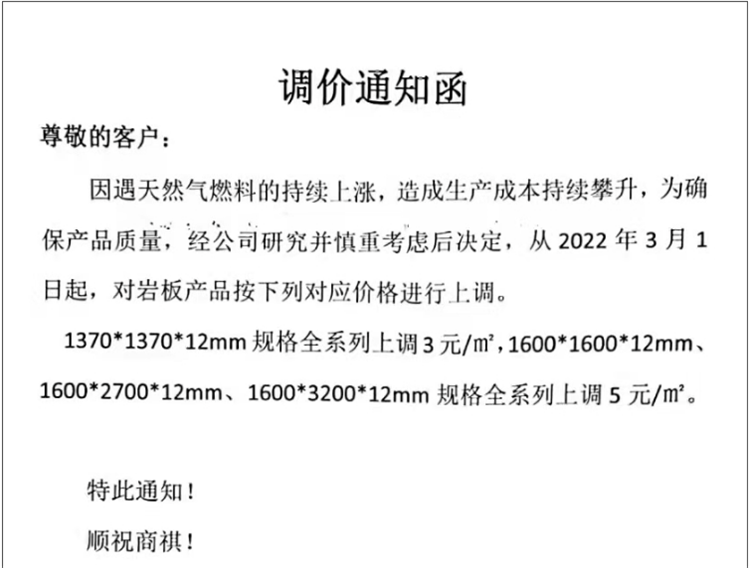

The first to start the "price rise" is the Jiangxi production area. On 18th February, two Spanish tile enterprises in Jiangxi issued the notice of product price adjustment, which decided to increase the price from 25th February, and all specifications of 300 × 450mm 6kgs Large plate tile, 300 × 400mm 6kgs Chinese Roman single wave tile are increased by 0.3 yuan / piece. On 25th February , a ceramic enterprise in Gao'an announced that the price of rock slab would be increased, 1370x1370x12mm all series will increase 3 yuan / m2, 1600x1600x12mm、1600x2700x12mm、1600x3200x12mm all series will increase 5 yuan / m2.

Some ceramic enterprises in Guangdong and Sichuan have also successively issued price increase notices in the near future. Among them, Guangdong ceramic enterprises began to adjust the price as early as 26th February , with a price increase of 1-3 yuan / piece; Sichuan ceramic enterprises have raised their product prices since March 1. The price increase categories include large plate, rock slab, medium slab and ceramic tiles, of which 750 × 1500 mm tiles increased by 2 yuan / piece, 300 × 600mm ceramic wall tiles increased by 0.1 yuan / piece.

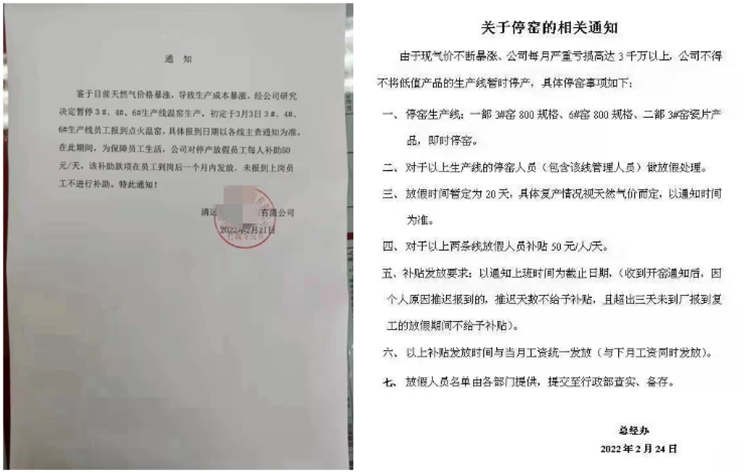

In addition, due to the large fluctuation of natural gas price, the ignition and kiln opening time of some ceramic manufacturers in Qingyuan, Enping and other production areas has been delayed, and some ceramic enterprises have suspended the production of warm kilns on the production line and postponed the ignition of warm kilns to early March; There are also ceramic enterprises that have to temporarily stop the production of low-value product production lines because of the sharp rise in gas prices and a monthly loss of more than 30 million; There are also a number of ceramic enterprises reduced the production on the production lines.

Generally speaking, the current price rise trend of the building ceramics industry is between some regions and enterprises, and a large-scale price rise have not happened yet. Most ceramic enterprises / dealers are still on the sidelines because they have raised product prices by the end of 2021 and the market situation is cold, or they dare not ignite production because the gas price is too high. It is reported that due to the soaring gas price and the rising prices of other raw and auxiliary materials and chemical materials, the production cost has risen. At present, the operating rate in Guangdong production area has reached a new low for many years, and the kiln in Guangdong production area has been stopped or exceeded 50%.

Gas prices are uneven across regions

Guangdong ceramic enterprises may lose their production advantages?

At present, although the gas prices in all ceramic production areas are rising, the actual gas cost of ceramic enterprises varies. Compared with other production areas, the gas cost of ceramic enterprises in Guangdong and Jiangxi has increased significantly. The person in charge of a ceramic enterprise in Foshan admitted that at present, the price of natural gas in Guangdong fluctuates greatly, and the average price has exceeded 6 yuan / m ³, While the gas price in other production areas has increased slightly, it is basically maintained at 2-3 yuan / m ³, The production cost difference between production areas is 4-5 yuan / m2 (based on 800×800mm production cost). From this point of view, ceramic enterprises in Guangdong have basically no advantages.

It is understood that at present, the gas prices of ceramic enterprises in various production areas are not balanced. Some industry insiders concluded that the price of planned natural gas used by ceramic enterprises in Jiajiang, Sichuan has only increased slightly, not more than 3 yuan / m ³, The price of unplanned natural gas is about 7 yuan / m ³ ; So far, the planned natural gas in Jinjiang production area of Fujian has maintained the original price, which does not exceed 3 yuan / m ³, Minqing production area maintains more than 4 yuan / m ³; Faku production area in Liaoning maintained the price at the end of last year, less than 2.7 yuan / m ³; Shandong Zibo production area plans to basically maintain 3.8 yuan / m ³;Most ceramic enterprises in Jiangxi Gao'an production area use centralized coal to gas, and the coal price is calculated at the cost of 1700 yuan / ton, which is equivalent to Natural gas about 2.4 yuan / m ³ . In addition, some Gao'an ceramic enterprises using natural gas digest the rising costs by making large plate or high-quality differentiated products, so that there is room for the price of conventional products to fall after several rounds of increase last year. Overall, in terms of gas cost, Jiangxi production area has more production advantages than Guangdong production area which relies on natural gas.

The chaotic gas prices of ceramic enterprises have exacerbated the differentiation of production costs in the national ceramic production areas, which may affect the pattern of the national ceramic industry in the long run.

Post time: Mar-10-2022